contact@bluecircle-olefins.com

about us.

The first European 100% circular olefins producer

Net zero and circular society

Only by diverting from the use of fossil based feedstock and moving towards circular feedstocks the chemical industry can contribute towards a net zero and circular society

Strategic autonomy and security of supply

Made in Europe reduces supply chain risks and increases business resilience

First circular methanol-to-olefins

production facility

Blue Circle Olefins is developing the first circular methanol-to-olefins production plant in The Netherlands to supply 100% circular olefins to the European chemical industry

what we do

Making chemicals circular

ambition

Defossilizing the Chemical Industry

Our facilities will convert renewable methanol into ethylene and propylene, which are the basic building blocks of plastics and many other materials

- Paint

- Shoes

- Carbon Racing Bicycle

- Phone

- Toys

- Shampoo

- Windmills

- Solar Panels

- Sewer Pipes

- Power Cables

- and more...

Innovation

COLLABORATIVE INNOVATION

Defossilization of the chemical industry requires collaboration along the value chain. This is why we work with a “Coalition of Willing” both upstream and downstream in selected value chains.

We collaborate with methanol producers, olefin converters up to global brand owners to optimize supply chain efficiencies and secure viable business cases for 100% circular products. We create long-term and trust-based partnerships.

benefits

Key benefits of using circular olefins

Carbon Footprint

Reduction

Cut your product carbon footprints (including end-of life) with over 80% compared to traditional oil based olefins

Regulatory Compliance

Complying with all current and upcoming regulations related to safety, environmental impact and circularity

Product Quality

Advanced process ensures highest industry standard product quality and performance

Short

Time-to-Market

Product can be directly used in your existing value chains reducing time-to-market for the introduction of circular products

Resilience

Ensure security of supply for olefins in the current market dynamics

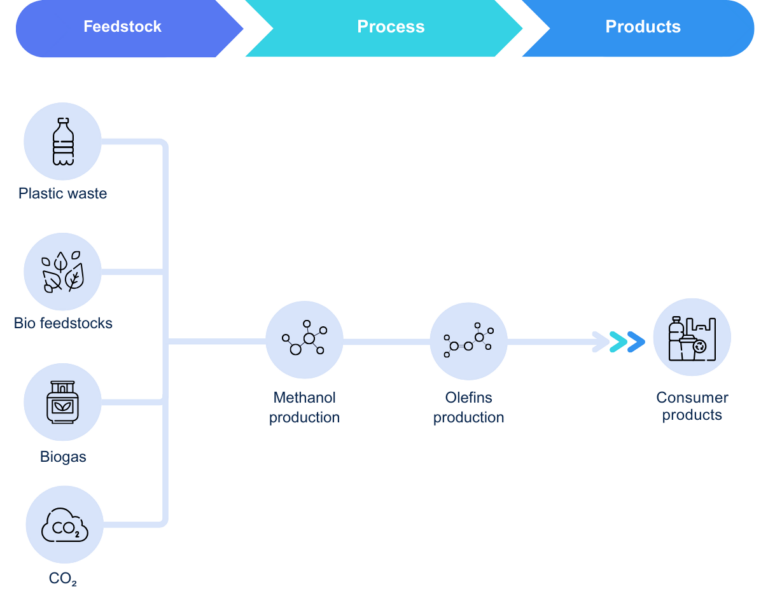

Multiple Green Feedstock Options

Upcycle plastic waste, residual biomass or CO2 into circular olefins depending on your client needs

impact

ENVIRONMENTAL IMPACT

Circular Ethylene and Propylene for the chemical industry

Emission reduction

Carbon Footprint

Scope 1,2 and 3 emission reductions potential of more than 100 Mton when replacing 30 Mton fossil olefins currently produced in the EU

Circular Feedstocks

Renewable methanol produced from second generation biomass, waste that is currently incinerated or biogenic CO2 and green hydrogen is used as a circular carbon feedstock

Electrification

The production facility will be fully electrified using green electricity, reducing scope 1 emissions to almost zero

Re-using Water

The MTO process produces substantial amounts of water that will be used to reduce the intake of fresh water

Project NL

first production facility

Blue Circle’s first 200 kton production facility will be located in Rotterdam, the Netherlands and will be able to supply olefins that can be used for the production of 100% traceable polyolefins or chemicals

meet our team

Proven track record

Project execution and

industrial innovation

Ralph holds a master’s degree in chemistry and in Business Administration from the Radboud University Nijmegen. He started his career in DSM in venture capital and business development.

After DSM, he founded several companies (Qlyte, Blue Fifty, Blue Care) and initiated several projects in green chemicals for Maire Tecnimont.

In 2022 he co-founded Blue Circle to enable circular olefin production.

Reinier holds a PhD in Chemistry from the Radboud University Nijmegen before starting his career at DSM. After several roles he was responsible for the global R&D strategy within DSM.

He continued his career at Bolsius and afterwards at TNO, where he was appointed as principal consultant Industrial Transformation.

He also was a board member of SusChem in Brussels, advising the European Commission on the transition to a Net Zero and Circular chemical industry.

Ralph holds a master’s degree in chemistry and in Business Administration from the Radboud University Nijmegen. He started his career in DSM in venture capital and business development.

After DSM, he founded several companies (Qlyte, Blue Fifty, Blue Care) and initiated several projects in green chemicals for Maire Tecnimont.

In 2022 he co-founded Blue Circle to enable circular olefin production.

Reinier holds a PhD in Chemistry from the Radboud University Nijmegen before starting his career at DSM. After several roles he was responsible for the global R&D strategy within DSM.

He continued his career at Bolsius and afterwards at TNO, where he was appointed as principal consultant Industrial Transformation.

He also was a board member of SusChem in Brussels, advising the European Commission on the transition to a Net Zero and Circular chemical industry.

news

Linkedin Feed

Latest News

Biomassa Feiten

Towards a net zero and circular chemical industry – the pivotal role of biomethanol as a global sustainable commodity

World Bio Market Insight

Blue Circle Olefins to revolutionize the chemical industry with circular olefins

Get in touch with us

Reach out for any inquiries, support, or to discuss how we can meet your industrial needs.

Address

Blue Circle Olefins B.V.

Weena 505, 3013 AL

Rotterdam The Netherlands

Request a call back

Please fill out the form below and someone from our team will be in touch.